Ningbo Ruicheng Packing expands film production to enter new markets

06 Nov 2024

Successful inline coater installation allows for improved sustainable PET film production

Ningbo Ruicheng Packing has successfully invested in upgrading one of its BOPET film stretching lines with Brückner’s newest Inline Coating Technology (ILC), aiming to open up new sales markets with expanded film production and thus to take another important step towards circular economy for plastic packaging.

Retrofitting of BOPET line using latest inline coating technology

Brückner Servtec has retrofitted the Brückner line with an inline coater (ILC), including integrated corona pre-treatment installations to improve further converting steps. The film application benefits gained from the upgrade are: improved printability, inline siliconization, antifog / anti-static and surface modifications.

The ILC technology uses the latest reverse single side kiss coat concept by Brückner. It is optimized for maximum convenience during operation in a BOPET line. This starts with the software integration in every line mode to make starting and stopping of the coating process a breeze. In addition, the gravure roller / coating chamber unit can be removed and cleaned without disturbing regular film production. All driven rollers are directly driven, as is usual in Brückner lines.

The project marks the first inline coater upgrade with the latest Brückner technology modifications for an existing PET line which has not yet been installed in any other line within China so far.

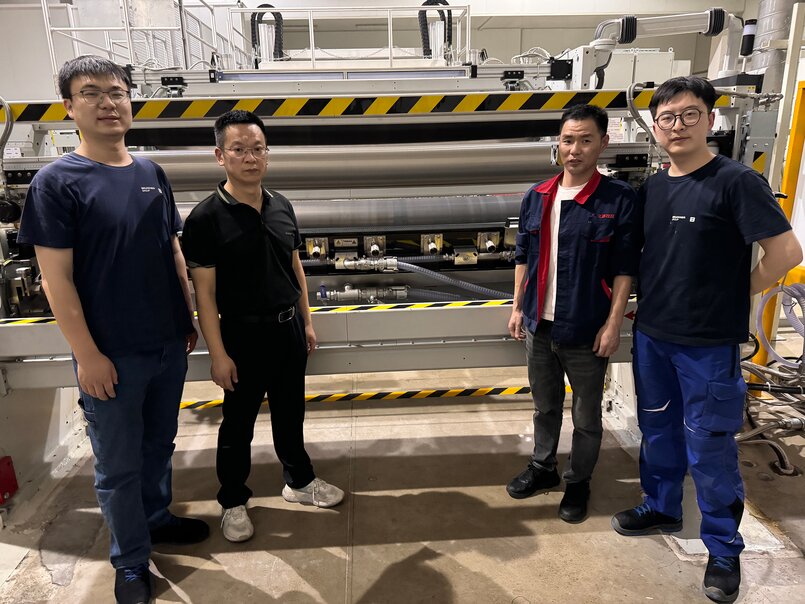

Successful start-up achieved by extraordinary team effort

In order to meet the scheduled start-up date, the local Brückner China team actively supported in the preparatory work for the installation, where the customer had already made foresightful arrangements for the construction. Without any language barriers, the Chinese installation teams achieved a very smooth cooperation, enabling a fast and successful start-up of the line.

Michael Zeiss, Project Manager, Brückner Servtec, adds happily: “My special thanks go to my colleagues and the whole team of Brückner Maschinenbau and Brueckner Group China (BGC). The successful completion of the project was only possible due to their strong support, flexibility, and hard work. Also worth mentioning is the great cooperation with the customer’s experts who brought the facility back into production quickly, efficiently, and smoothly!”.

Owner Mr. Shao Zheng was very satisfied with the upgrade result and states: "Thanks to the support of the whole Brückner team, we've managed to make a good start-up for the inline coater. The cooperation between both teams was full of respect and contributed to the success of this project. After several tests, we now produce good PET films in high quality for our customers."

The convincing performance of the modernized film stretching line, combined with the new ability to produce high-quality PET films, allows Ningbo Ruicheng Packing to look very confidently to the future of sustainable packaging structures.