Energy Audit

Energy optimized production process

Efficient energy use in film production is more important than ever since it is an increasing proportion of the manufacturing costs and part of a sustainable production. Therefore, energy saving concepts have been in our focus for a long time.

However, many older lines do not apply state-of-the-art technology, but use old components which are not so much focused on saving energy but on other features. Nevertheless, every single unit of wasted energy, no matter whether mechanical, electrical or thermal, is gone – paid for but unused. Today’s technologies offer a far better energy balance compared to older equipment.

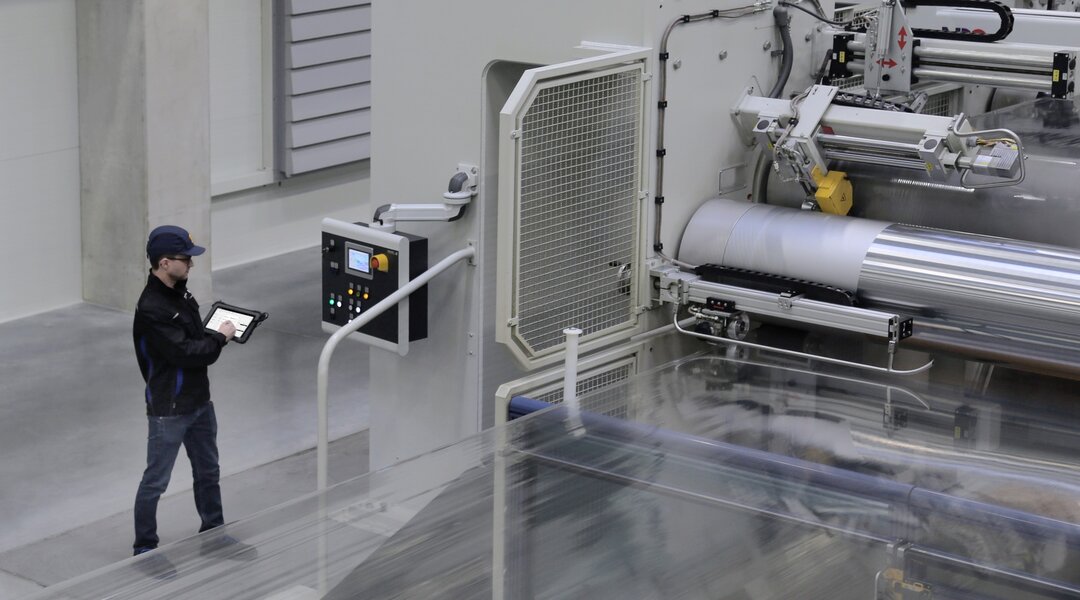

Before investing in any energy-saving modification on a film stretching line, it is useful to start with a professional analysis of the current energy-balance of the line. The specialists at the Energy Audit evaluate the line intensively regarding the more efficient use of oil, gas, electricity or other sources. Afterwards, a set of custom-tailored recommendations shows the most efficient potentials for energy saving. Sometimes, even small alterations to older lines can result in big energy savings.

Benefits

Individual line assessment

Customized recommendations

Experienced auditors

State-of-the-art measuring equipment

Reduced operating costs

Comprehensive report

Leading to more environmentally friendly production

Which parts of the plant are covered?

- Material supply

- Extrusion and stretching line

- Electrical system

- Utilities and surroundings, e.g. energy supply, air conditioning