Stay-up-to-date with Brückner TEC Talks

Boost the efficiency of your film production

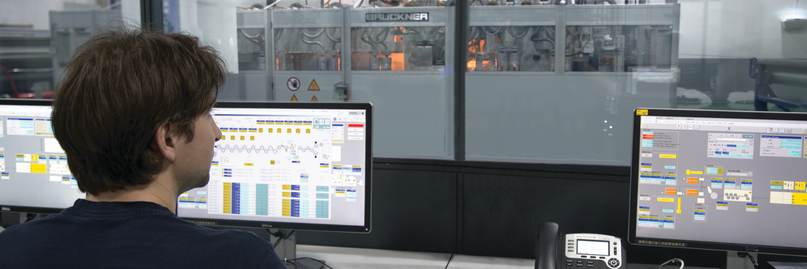

At Brückner, we strive for excellence and are constantly looking to innovate by introducing new technologies throughout all areas of our industry. This includes smart and feasible solutions for a safe and profitable operation of your plants to ensure the maximum availability of your line in the future.

With Brückner TEC Talks, our digital communication series, our experts inform you about the latest findings on market developments, advanced innovations and new technologies. Additionally, you will receive useful information and tips about the film production process that will make your work even more efficient.

All TEC Talks videos available in Member Area:

Service means understanding the needs of our customers. That's why we have set up a members' area exclusively for our customers.

The Member Area includes

- Media library with all TEC Talk videos

- Market news

- Expert interviews

- Brückner ONE Tutorial Videos

- Brückner Sustainability TV

Your advantage: You can watch the videos at any time - exactly when it suits you best.

Register for free in the Member Area and enjoy all TEC Talks videos on demand

Previous Brückner TEC Talks

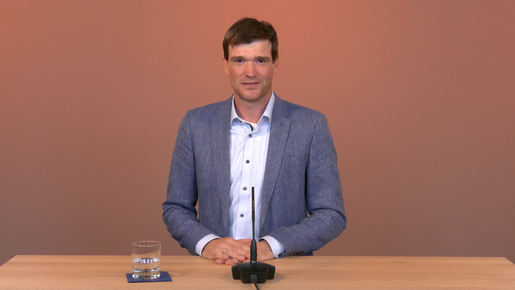

Inline Coating: Small Layer, Big Impact

July 2025

Can a thin coating layer transform sustainable packaging? Yes, it can—thanks to Brückner’s inline coating technology.

Enhancing the barrier properties of BOPP films is a key step toward fully recyclable and sustainable packaging solutions. With our innovative inline coating (ILC) technology, we’ve made this step a reality—enabling ultra-thin layers that significantly improve film performance and open new possibilities for modern, eco-friendly packaging.

In our this TEC Talk our expert Benedict Orterer shares how this cutting-edge technology is reshaping the packaging industry.

What to expect:

- Key factors for next-generation packaging solutions

- Insights into 2-ply and 3-ply laminate structures

- How Brückner’s ILC solution delivers measurable benefits

Next Generation IMC

May 2025

Future-proof film production

Is your film stretching line aging - Brückner or not - and you want to secure its future? Challenges like limited spare parts, outdated visualization, or upgrade limitations may arise.

In this TEC Talk, Gerald Huber shows how the latest Integrated Machine Control (IMC) can modernize your line. Learn about the IMC development journey and why upgrading your IMC is a smart move for long-term performance and reliability.

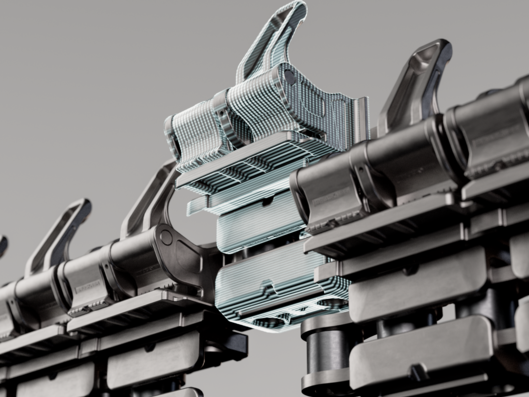

Chain Track System FOK 8.8

March 2025

High performance solution

Brückner's innovative sliding chain track system FOK 8.8 enables film stretching up to 700 m/min - and is available as a retrofit for existing lines. Learn how you can maximize output, reduce maintenance, and extend line lifetime with a proven, future-ready technology.

Join us for an in-depth look with our expert Hugo Seel at the technical features and benefits.

Line Conversion to PLA & PHA Films

January 2025

Home compostable bioplastic films

Home compostable PLA and PHA films meet environmental challenges and position your company as a pioneer in sustainable innovation.

In this TEC Talk, our process expert Heiko Krippner explains the benefits of PLA and PHA films and explains in detail how to adapt your equipment for the shift to eco-friendly film solutions.

Advanced Virtualized IMC System

November 2024

The key to longevity of your line control system

In this TEC Talk, you'll will uncover how virtualization is redefining the way we maintain film stretching lines. As aging hardware becomes harder to replace, transitioning to modern systems is no longer optional - it's essential.

Discover how virtualization keeps systems future-ready, extends equipment lifespan, and minimizes downtime. Join our expert Christoph Vogl as he shares Brückner's innovative virtualization strategies, from the Hypervisor layer to a step-by-step guide on implementing these advancements.

Precise Thickness Measurement

September 2024

Upgrade improvements for the thickness profile

In this TEC Talk, our expert Stefan Mayr analyses in detail thickness measurement and control systems of film stretching lines.

You will get useful information on:

- Various gauge suppliers and their specifications

- Pros and cons of different measuring methods

- Upgrade options for existing thickness gauges

- Introduction of the new thickness control software TCE 2.0

What’s new in Digital Solutions and Services

November 2023

For a smart and flexible film production

In our expert panel, we talk about digitalization trends in the biax-industry: What's behind this megatrend and how the new features of the Brückner ONE digitalization makes your daily work at the film stretching line easier:

- Paperless and simple-to-use technical line documentation

- Quick and easy spare part identification and inquiry

- Fast resolving of service requests

- Lifetime line history

- Tools for quality and efficiency improvements

New Machine Technology for Existing Lines

April 2023

How to boost efficiency and profitabiliy of your film stretching line

Brückner has always invested a lot in R&D to be the pioneer in film stretching technology. We at Brückner Servtec use this know-how and these tools to modernize existing machines and increase their productivity, improve film quality and make them even more economical.

The focus of this TEC Talk is to make your line competitive again in view of the large number of new lines that have come onto the market in recent years. From the wide range of possible improvements, our experts will present some examples to meet the above mentioned goals of film manufacturers.

Participants will learn:

-

Why double nip rolls improve the film quality

-

How direct flake dosing is boosting your line

-

How an IPC modernization improves the line's efficiency

The Servtec Experience

November 2022

K2022: Review and Insights

This time, we showed how we support you throughout the whole lifecycle of your film stretching line to ensure maximum availability. We call it "The Servtec Experience".

You couldn't visit us at the K show in Düsseldorf? No problem. We also reviewed the latest trends, insights and technologies from the K show and discussed them.

Global Service

June 2022

100% know-how in film stretching in a single person? Impossible? Not at Brückner!

The last two years, with the COVID 19 pandemic and all the travel restrictions that came with it, have given us a serious reminder of how essential professional service is to the efficient operation of film stretching lines. Therefore, we focused on Global Service in this TEC Talk and took the participants behind the scenes of our advanced and expanded global service organization.

Our experts Heinz Lind and Christian Stadler showed in detail how our special services can help our customers to get their film stretching line up and running again more quickly in the event of troubleshooting, thus saving them a lot of money.

Additionally, they learned more about our new strategy "Think global, act local" which creates a unique worldwide pool of know-how for our specialists on site with our customers.

In our look behind the scences the attendees also got to know Brückner specialists from their region. They explained their specific solutions to support film producers in the most efficient way.

Energy

April 2022

Starting with the current global mega trend "Sustainability" in our TEC Talk in December 2021, we continued within our series with the next hot topic "Energy" in April 2022. Hosted by Erich Huber (Senior Regional Service Manager), we focused on:

- Energy-Monitoring: Tools to make energy usage transparent

- Energy-Saving: Measures to reduce the energy consumption of production lines

- Energy-Reuse: Options to reuse energy in the production cycle

Through continuous development, Brückner has cut the energy consumption of modern film-stretching lines by almost half in the last two decades. However, we remain ambitious: we are constantly optimizing our products to further decrease the use of energy.

In this TEC Talk our experts Stefan Mayr (Project Manager Electrical Upgrading), Sebastian Salentin (Project Manager Mechanical Upgrading), Heiko Krippner (Process Engineer) showed in detail how to influence, and especially reduce the energy consumption of existing production lines with special upgrades, tools and services.

Sustainable Film Production

December 2021

In our last Brückner TEC Talk in 2021 we focused on one of the current global mega trends: Sustainability.

The participants learned in detail how to realign their production for sustainable film types with mono-material structures, e.g. BOPE, BOPET and BOPA. Our experts showed how these line concepts for fully recyclable packaging solutions meet the current and future market demands.

The participants also experienced how Brückner supports film manufacturers during the whole lifecycle of the film stretching line, which is the prerequisite for a successful, profitable and especially sustainable film production for decades. The following topics have been also highlighted in this context:

- Improved quality (more A-grade film, less waste)

- Increased yield (line availability)

- Reduced ressources (raw material and energy consumption, optimized operation)

Line Conversion - New Products

October 2021

What to do with older lines? Our experts Christian Aigner, Hugo Seel and Sebastian Salentin showed how line conversion can transform existing film stretching lines into profit boosters.

Especially older lines, whose output performance does not match the state-of-the-art anymore, can no longer compete with new, high-performance lines. Therefore, these film producers need completely new possibilities for the use for their production lines.

Our experts presented practical examples of line conversions to run new products, so-called specialities. They explained in detail what needs to be adapted of an existing line to produce value-added film in order to stay competitive:

- Various types of multilayer film (cavitated film, improved surface film or barrier film)

- Inline Coating (ILC) to improve the film quality with a 3-layer die (mono-material structure)

Process Optimization

July 2021

Process related topics can be very diverse in a film stretching line, especially when you consider the various film types. Furthermore, they have a huge impact on the film quality.

Our process expert Lukas Krems gave useful hints for various parts of a film stretching line in order to optimise the system in terms of process related challenges.

He took a closer look at:

- Twin screw extrusion

- MDO stretching section

- TDO clean oven

- Winder system

Clip & Chain

April 2021

In this TEC Talk, Brückner Servtec addressed the importance of a Professional Clip & Chain Service. Our Brückner Experts Benedict Orterer and Markus Summer pointed out that the TDO chain-track system is a vital part of any biax film-production line, which needs high attention and regular maintenance to ensure maximum production availability and efficiency.

The two specialists from the machine process and mechanics area shared their personal experience and knowledge with the viewers about the following points:

- How the chain-track-system directly influences the film quality

- Why regular maintenance of the TDO chain-track-system is necessary to have a healthy production line

- Why increasing lubrication causes more damage to the chain than improving its conditions

- What a Professional Clip & Chain Service by Brückner looks like

- Which steps do you need to take and what are the key benefits

Digitalization

December 2020

Brückner Servtec introduced and showcased different functions of the new Brückner ONE Digital Service Platform in the first event of the TEC Talks series. The two experts Jürgen Zinner and Daniel Mieze familiarized the participants with everyday service processes and discussed key benefits:

- Line documentation in a digital library

- Spare parts easily found and ordered

- Enhanced communication opportunities

- Creating a service request using smartphone and desktop

- Benefits of the new support tools on the platform

- Data protection and highest security standards

- Enhanced control over remote access