We preserve the environment

Protecting nature through the responsible use of resources and products has been part of our DNA since the beginnings of our family business.

Our products and services are designed to further decrease the use of raw material, lower energy consumption and other operating resources for film stretching lines. Additionally, we support our customers to produce recyclable packaging, e.g., with bio-polymers or mono-material structure such as BOPE film.

The professional use of digital services allows us to reduce the CO2 footprint by avoiding unnecessary traveling of service engineers, fasten problem solving and minimize downtime of machines.

Climate

We protect the environment and resources

Climate protection is first and foremost about reducing energy consumption and the emission of harmful greenhouse gases. Since 2000, we at Brückner have reduced the energy consumption of our film stretching lines by almost half. And we remain ambitious: we are constantly optimising our proven measures.

Sustainability is already a major focus at a sustainable and energy-saving design of the machines leading to the highest possible resource efficiency. On top, our engineers and scientists are working on energy recovery systems to re-use the energy generated during production so that not a single spark of energy is wasted.

We act sustainably through our "Think Global - Act Local" mindset, in which we transfer products and services to our worldwide local platform companies and their specialists. This includes our clip and chain refurbishment centers in every part of the world, such as: USA, Colombia, Slovakia, India, Thailand and China.

Circular economy

Need for recyclable packaging

Doing great things together

A strong circular economy needs joint forces of all players along the entire value chain: raw material manufacturers, machine suppliers, film producers, converters, packers, brand owners, traders, consumers, waste collectors and sorters, recycling companies. The outcome of our collaboration with our sister company Brückner Maschinenbau and all partners sends a clear message: provide recyclable packaging that enables circular economy.

Together, we identified three challenges for the circular economy. First, the need for mono-material packaging solutions which can replace multilayer laminate films made of different raw materials. These types of films are easy to sort and easy to recycling. Second, the need for established recycling streams, easy to use for consumer and efficient production of recycled materials. And third, the need for good quality of the post-consumer recycled (PCR) material to guarantee film producers high productivity i.e. the in extrusion system or in the stretching part of the lines.

Packaging materials ready to recycle, the use of post-consumer-recycled materials and compostable films are our solutions to enable the circular economy. Thus, we developed several film types and recipes to fulfill these sustainability goals

Brückner provides various solutions for film producers to convert their film production to the circular economy. Since the new materials may not have the high market demand already, it is more economical to produce them in smaller quantities. For new lines, our sister company Brückner Maschinenbau developed with several partners a 100% mono-material BOPE packaging film which can be produced on a hybrid BOPE/BOPP film stretching line.

For existing machines, which are smaller for example and cannot compete anymore with commodities, Brückner Servtec offers line conversion upgrades to BOPE film production. The line has to be mainly modified in the dosing unit, extrusion system, casting unit and die, and in the MDO (all depending on the prevailing situation on-site).

Cooperations for a sustainable future

From bilateral teamwork with raw material suppliers, masterbatch specialists and film producers to more complex cooperations along the value chain: Brückner is involved at many levels.

Examples:

- DOW

- SABIC

- CONSTAB

- NOVA Chemicals

- Circular Plastics Alliance

- CEFLEX

- PrintCYC

- R-Cycle

- Blue Competence

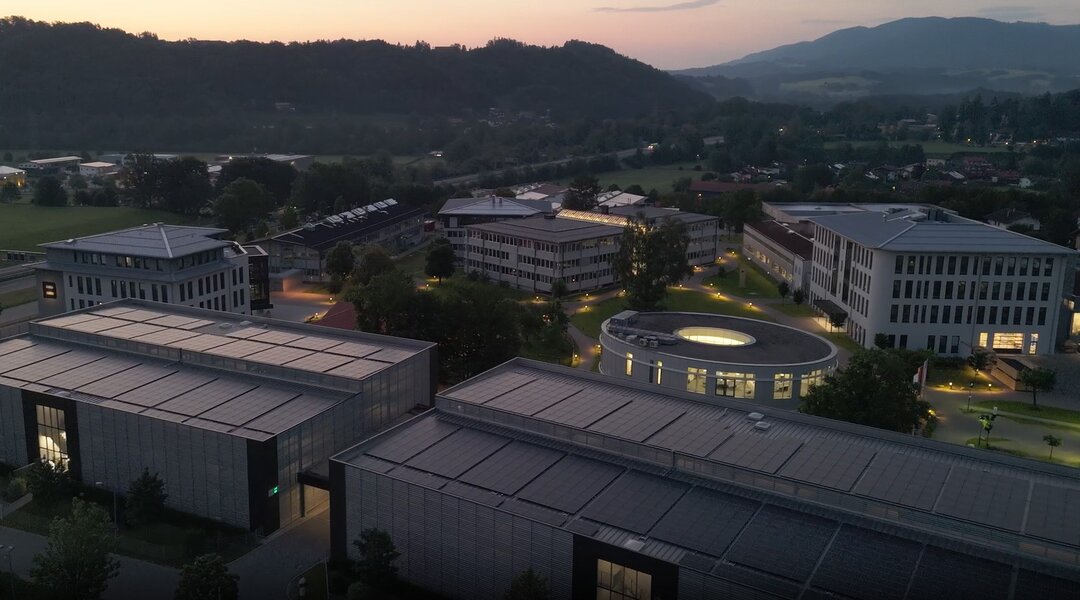

In the course of waste management, the site relies on the use of a professionally designed waste site as a recycling centre in order to be able to better separate plastics, paper, biowaste, steel, sheet metal, electronic scrap and residual waste and thus reduce the amount of residual waste to 10% of total waste. Already today, our waste is sorted again in appropriate facilities after collection. Pure plastics are filtered out and go partly to the plastics processing plant and partly to the substitute fuel processing plant. This also applies to the plastic waste from our technology centre.

In all new construction projects, the site management also pays attention to minimising the CO2 footprint or implements measures to improve the air supply. With sustainable landscaping of extensive green and flowering strips between the buildings and a specially created bee pasture, the site offers more stable living conditions for the resident insects and thus contributes to their survival. In addition, in order to preserve as much green space as possible and seal less land, employees have access to two modern, multi-storey car parks instead of large parking lots with about 40 e-charging stations. We cover part of our daily electricity requirements with photovoltaic systems with an installed capacity of 505 kWp on our company premises since spring 2024. The local canteen uses primarily regional products every day instead of food that has already travelled "halfway around the globe". In this way, every measure, no matter how small, supports our efforts for a more sustainable future at the Siegsdorf site.