Brückner Servtec Strengthen its Business Field for Clip and Chain Overhaul

15 Jun 2018

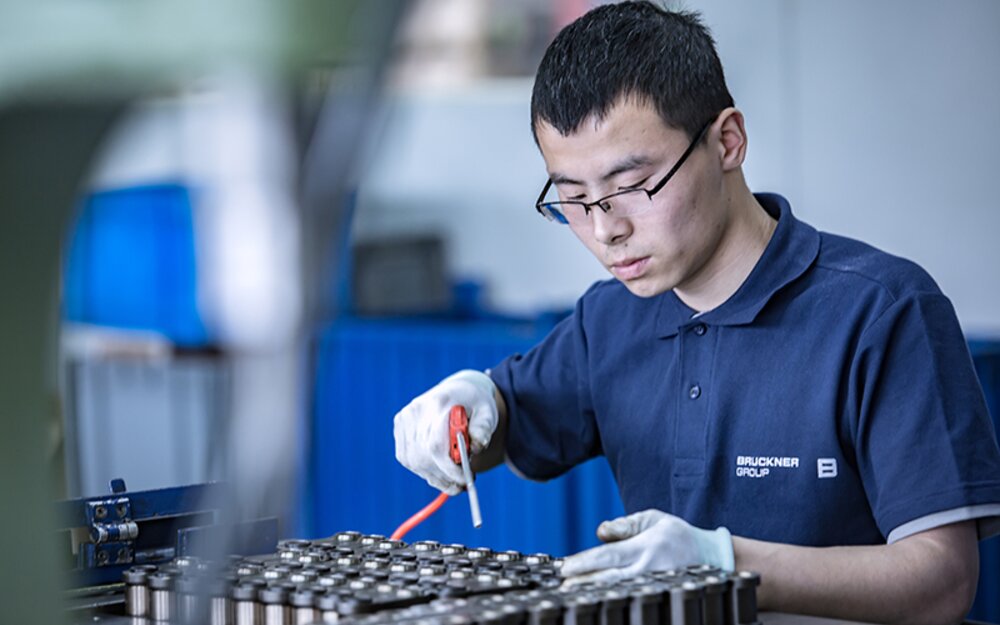

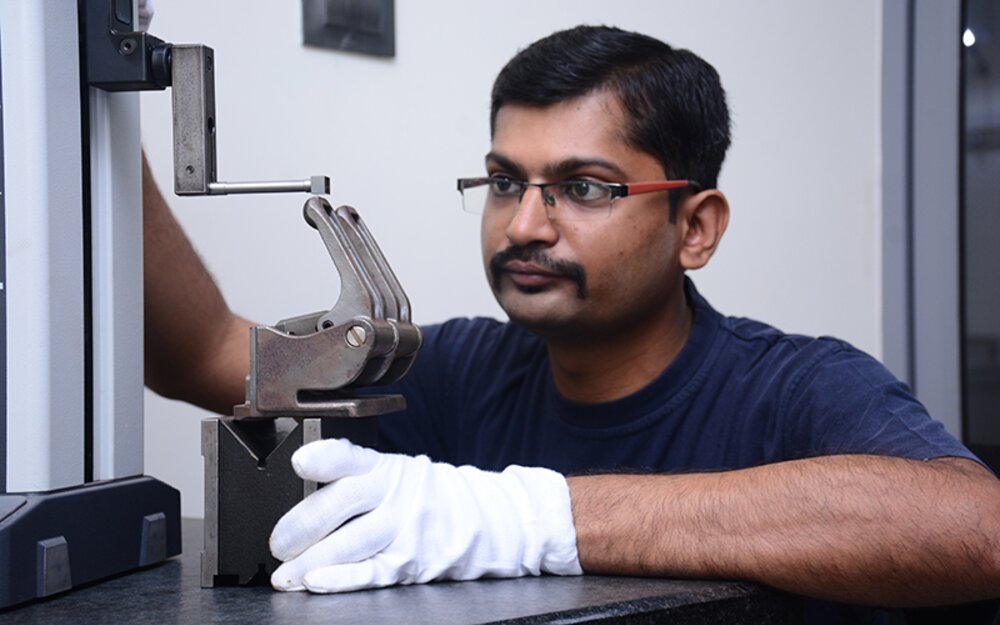

Professional overhaul processes at all Brückner locations worldwide for more customer value

The TDO clips and chains belong to the core of a film stretching line. Their correct overhaul is of crucial importance to the line’s performance, its process stability and hence the uptime of the line. However, the overhaul is technically demanding and requires precise know-how and processes. Therefore, Brückner Servtec offers professional clip and chain service locations in virtually every part of the world, i.e. Colombia, Slovakia, India and China. In order to enhance the service quality even more, fasten processes and increase the benefit for customers, Brückner Servtec continuously strengths its competence and quality at its clip and chain overhaul locations around the world.

The advancement includes two steps: first of all, the locations will have the same state-of-the-art tools, devices, measuring and test equipment. The result of the overhaul is superior when the most accurate technologies available on the market are used. Since all locations have the identical machine pool, the employees are familiar with the equipment worldwide and can easily support other facilities. This flexibility shortens delivery time for the overhaul.

Secondly, Brückner established an own field of responsibility for clip and chain overhaul, led by Brückner Servtec at the headquarters in Siegsdorf / Germany. These experts will intensify the international cooperation and exchange of knowhow among the single operations worldwide. Insights are given on new technical developments in this field and staff trainings performed in order to assure more efficient overhaul processes.

Why clip and chain overhaul by Brückner?

Brückner offers the overhaul service for all types of clips (all FOKs) and chains (roller and sliding). Since we developed and designed the parts as OEM (Original Equipment Manufacturer) we know how to deal with them best. This ensures the best treatment for the equipment in shortest possible time to reduce your maintenance downtime and increase profitability. The professional overhaul includes:

- The first step is a free evaluation of sample parts by Brückner Servtec in Germany. Afterwards, Brückner makes a condition assessment of specific parameters of the clips and chains.

- The disassembly of the parts is carried out with special devices which were developed by Brückner. Following a wear and tear check and replacement of worn parts.

- The cleaning of the parts is done with specific solvents and cleansing agents, which will be disposed by Brückner according to the law in force afterwards. Additionally, the surface of the parts can be treated and repaired, if necessary.

- The last step is the assembly with special Brückner devices, a final quality inspection and professional packaging to protect the parts in the best possible way.

The service is also available for non-Brückner lines.

Click here for more interesting information about clip and chain overhaul.