Shandong Qunli relies on digitalization platform Brückner ONE

06 Aug 2024

First retrofit of the Brückner ONE modules Production and Analytics in an existing film stretching line enabling efficient digital service processing

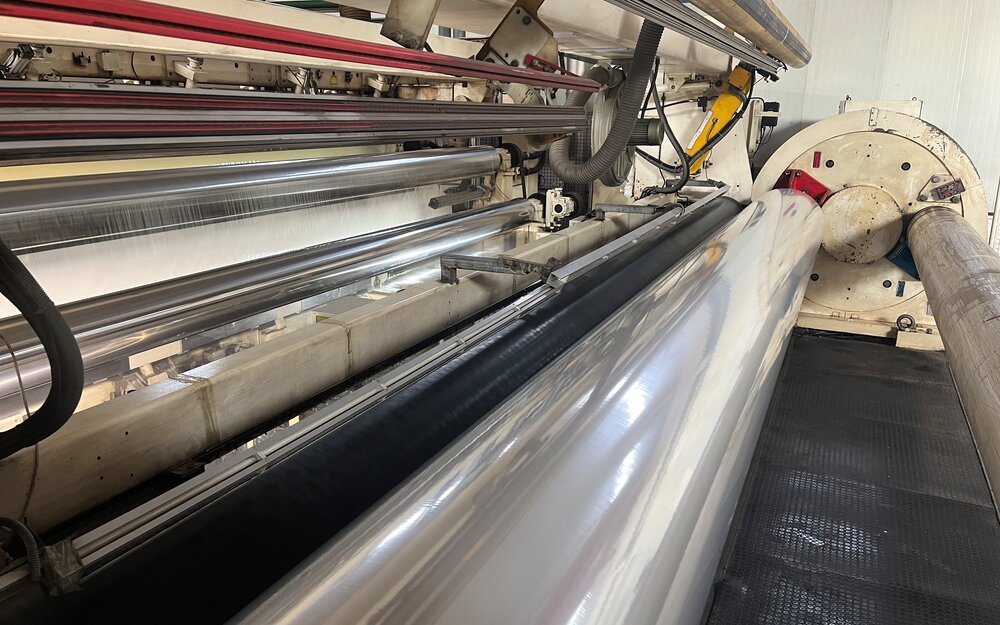

For the first time in the history of Brückner Servtec, an existing BOPP production line was retrofitted with the Brückner ONE modules Production and Analytics. As part of an Integrated Machine Control (IMC) upgrade, the film stretching line of the customer Shandong Qunli Plastics (China) received also a new automation software, enabling a new level of digitalization.

Improved efficiency for optimal performance

The entire implementation of the software and the digital Brückner ONE products included new IT hardware, such as servers and system control components. For example, the discontinued B&R system, installed over twenty years ago, was replaced with the latest Siemens control system, including all I/O modules. New user interfaces (for IMC and Brückner ONE) were also installed, ensuring improved line efficiency for optimum performance.

Furthermore, additional IMC installations and updates were conducted on numerous other line components, including the thickness gauge or the dosing units on the main extruder in order to implement the most recent technological advancements.

Project highlight: Retrofitting the digital Brückner ONE modules

A project highlight was the implementation of the two Brückner ONE modules into the existing film stretching line. In contrast to new lines, where they are already part of the system this was the first time they were completely retrofitted.

-

The Production Module displays all the functions and features of the system software for controlling the plant production. It includes assistance systems such as the Cockpit, covering all relevant information in one page or the Thickness Control Engine (TCE) for measuring the thickness profile. More information on the tool here.

-

The Analytics Module enables performance tracking of the line and conclusions to be drawn about film production by one click. Included tools are for example, the Recipe Manager (managing existing recipes) or Raw Material Manager (material tracking). More information on the tool here.

By retrofitting the two modules, including the desired assistance systems and auxiliary tools, Qunli received the latest digital software developments of Brückner ONE, supporting its system operation and benefiting from increased efficiency, an optimized production process and cost-effectiveness in the long term.

Fast upgrade process results in high customer satisfaction

The upgrade project was completed within four weeks, after which the production line was successfully restarted on time, a week and a half ahead of schedule.

Since the restart the production line has been running smoothly and Mr. Wu Changshuo, Chairman of Shandong Qunli, expressed his satisfaction with the results of the upgrade: “Thanks to Brueckner employees’ hard work, our line takes a new lease of life after the successful IMC upgrade”.

Mel Sauer, Installation Supervisor at Brückner Servtec, is also very satisfied and sums up: "The earlier start-up date was mainly due to the good cooperation and the dedicated efforts between Qunli, its personnel and the Brückner colleagues. The customer met our requirements for the installation of the new components very well, which created the basis for the fast recommissioning of the plant.”

Brückner Group China Customer Manager Katie Li adds: "We thank Shandong Qunli for their long-standing trust and loyalty in our innovative film stretching services and the good personnel cooperation, which made this project a huge success!”.

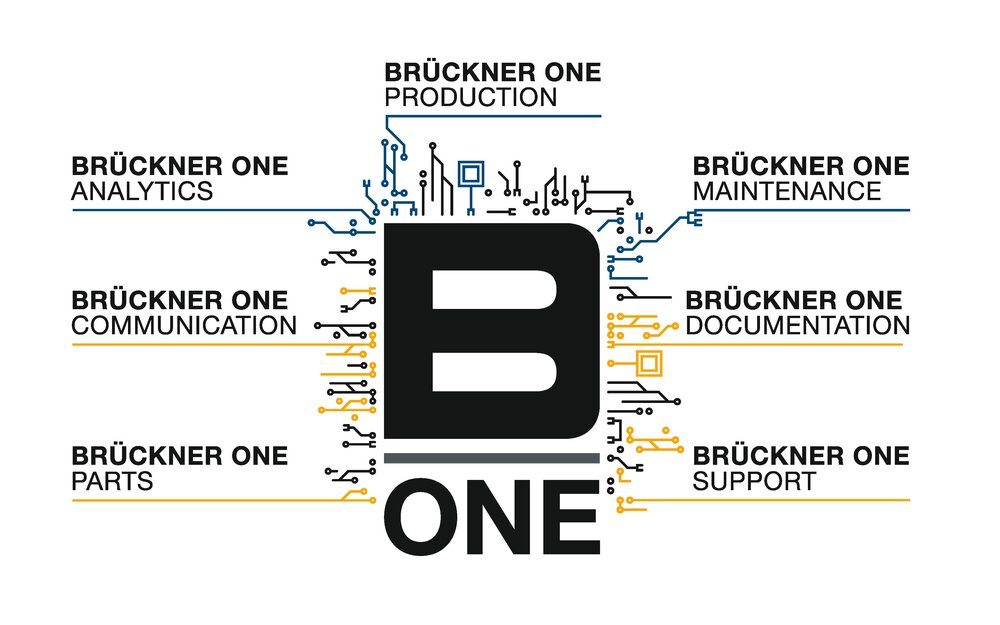

About Brückner ONE and its modules

Brückner ONE is the digital touchpoint that supports all aspects of the film stretching line and its operation, coming with seven modules (Support, Documentation, Parts, Communication, Maintenance, Production and Analytics). As part of the IMC upgrade, the last two modules were subsequently installed in the line’s system. More information about the digital platform Brückner ONE can be found here.