Upgrade from cascade to twin screw extrusion with special conveying system

20 May 2011

There is a longstanding relationship between Taghleef Industries (Ti), one of the largest manufacturers of BOPP and CPP films in the world, and Brückner Servtec. After various joined projects at other BOPP lines of Ti’s huge technology park, the 6,6m-line at the site in Hungary has been recently upgraded with twin screw extrusion system, new resin supply system and a state-of-the-art Brückner Integrated Process Control System (IPC).

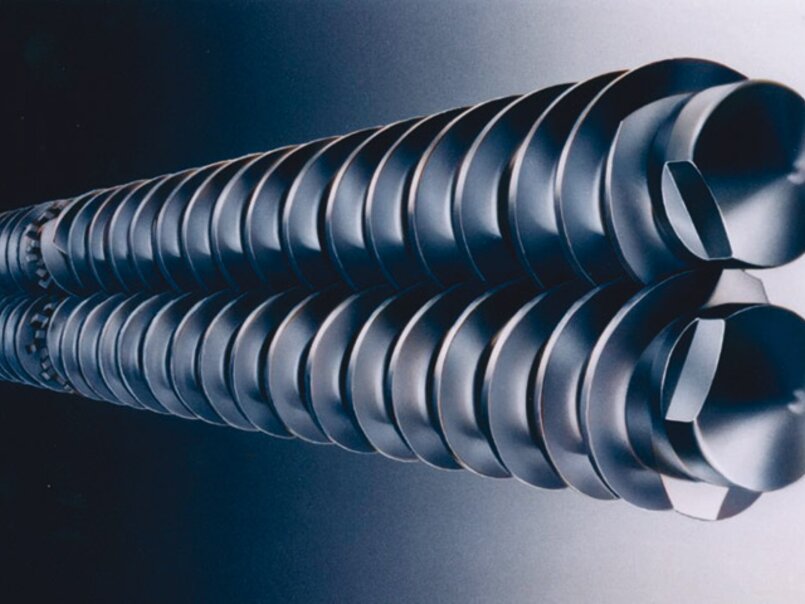

Helix resin conveying system

Brückner Servtec replaced the cascade extrusion unit with a twin screw system. Normally, this requires a higher located raw material supply for the new system. Hence, the production hall needs a minimum height as well. Since the production hall at Ti’s site does not have the required height for twin screw, a solution had to be found. A common, however, costly way is to rebuild the hall and make it higher. In order to avoid this modification, Brückner Servtec installed a helix conveying system at Ti’s line. This allows tremendous height reduction of the system and a simple connection of the existing raw material supply system to the new extrusion unit. Due to this special conveying system, Ti did not have to make any modifications at the building. Ti is satisfied with Brückner’s solution which was applied the first time at a BOPP line.

High performance twin screw technology

With twin screw technology, Ti benefits from:

- Minimum place requirements

- Low energy consumption

- Wide and flexible output range

- High recipe flexibility by direct component dosing

- Perfect homogenization

- Simple handling by proved Brückner automation

Improved winder changing procedure with AC drives and new IPC system

Installing AC drives and the new Integrated Process Control (IPC) system, Brückner Servtec could also reduce the change over time at the winder drastically. That means for Ti to have more good film on the winder and additional output. Brückner’s Integrated Process System consists of one single system for the control of the entire line. Since there is less variety of installed hard and software, costs for the system’s maintenance, service and support are much lower, compared to standard systems which include several suppliers. Brückner’s film specific IPC system works with reprogrammable operation steps which enable easy, faultless and fast operation of the line. All system components are integrated into the plant’s network for centralized management and support.

The smooth and efficient realization of the project reflected once again the good cooperation between the project teams of Ti and Brückner Servtec. The project was finished ahead of schedule and Ti had good film on the winder within a few days.